Thomas Steele Presents:

How Materials & Finishes Affect the Durability of Site Furnishings

From Graber Manufacturing, Inc.

In this recording of Thomas Steele's How Materials & Finishes Affect the Durability of Site Furnishings webinar, we go into detail about the qualities of the different finishes and materials present in outdoor furnishings. This webinar was originally recorded on February 25th, 2021.

Host: Sam Simon

Facilitator: Chantel Pivotto

Panelist: Andrea Landmann

STEEL

More often than not, an outdoor site furnishing will incorporate steel in some way, whether that be in a singular component, as the frame of a piece, or the piece in its entirety. Steel's ability to be bent into different forms and remain durable in natural environments makes it very desirable material for outdoor products. It’s also a material that can be produced and sourced within the United States, allowing the product to meet made in America standards.

According to American Iron and Steel Institute, steel is 100% recyclable, which means that it can be recycled repeatedly while still maintaining its quality. There is no loss in durability with recycled steel, which makes it a great sustainable material.

Typically, outdoor furnishings are made from structural grade steel, such as A36 and cold finished 1018.

A36 is a structural, mild carbon steel. Its strength, formability, and excellent welding properties make it suitable for a site furnishing application, where it will be welded, bent, and fabricated into different parts of furniture pieces. Things like straps and slats on benches are typically made of this type of steel.

Cold finished 1018 is a general purpose, low carbon steel that produces a hard, uniform case, making it a great material for outdoor furniture fabrication. Examples where you might find this steel are in bench legs and trash receptacles.

With that, beyond its general strength characteristics, there are different types of steel to be aware of and each one has a slight difference in terms of its ability.

GALVANIZED STEEL

Our galvanized steel products have been hot-dipped galvanized, or HDG, which is the process of dipping fabricated steel into a kettle or vat containing molten zinc. While the steel is in the kettle, the steel metallurgically reacts with the molten zinc to form a tightly bonded alloy coating that provides corrosion protection superior to that of just raw steel.

Because it provides long-lasting resistance to corrosion in outdoor environments, galvanized steel is a material commonly used by Thomas Steele. It is an incredibly durable finish that is great for installations in wet and snowy environments, and it resists common wear and tear, such as scratches and scrapes. What’s interesting about galvanized steel is that if it does get scratched, the zinc sacrifices itself where corrosion would be attempting to attack the steel, and keeps the corrosion from spreading.

Because of its protective qualities, galvanized steel requires almost no maintenance. However, compared to some of the other steel finishes, galvanized steel is slightly more susceptible to rusting in salty environments, such as coastal regions.

Galvanized steel is also not an ideal material for fabricating lighter gage applications. Items such as litter receptacle lids should not be made with galvanized steel because the galvanizing process makes it difficult for thin sheets of steel to keep their form, as they are likely to warp during the hot-dip process.

You will likely recognize galvanized steel by its greyish, almost silver appearance. After years of being exposed to the elements, however, it will have a more subtle, battleship grey color. One popular design for commercial site furnishings you’ve likely seen has been to pair galvanized steel frames with wood or recycled plastic surfaces.

Hot dipped galvanized steel can have a rough feel to it, and for this reason it’s not often used to create surfaces, such as tabletops or seats, for site furnishings. You are more likely to find it used as the frame for a piece of furniture, or as other support components, like table bases or stool legs.

STAINLESS STEEL

Stainless Steel is an extremely resilient metal that comes in different levels of durability, referred to as grades. While there are many grades of stainless steel, the two we will be focusing on here are 304 and 316 grade.

Grade 304 is the most common type of stainless steel, and it is used in most applications.

Grade 316, also known as marine grade, contains a higher level of nickel, which makes it more resistant to corrosion in salty environments.

Typically, the finish you’ll find when selecting stainless steel from Thomas Steele is a #4 brushed finish. This finish is created by sanding the stainless steel in one direction with a 120 to 180 grit belt, followed then by softening with an 80 to 120 grit medium, non-woven belt. This brushing effect creates a distinctive look with a pattern of fine parallel lines.

Electropolishing is another finishing process for stainless steel.

Electropolishing stainless steel is a reverse plating process that uses an electro-chemical solution to remove the outer layer of the metal, while also removing impurities. By dong this, the process removes unwanted contaminants and other surface imperfections that could compromise the long-term integrity of the metal. This process creates mirror-like appearance on the metal, giving electropolished stainless steel its unique aesthetic.

When comparing the #4 brushed finish to electropolished stainless steel, both are highly corrosion resistant, however, the electropolished finish is slightly more durable because impurities have been removed, and the brush marks left on the #4 brushed finish make it just slightly more vulnerable to corrosion.

Stainless steel should be considered for installations where furnishings will be in contact with salty ocean air and other tough environments. It is also a great choice as a tabletop material because of its high resistance to scratches and the fact that those scratches won’t corrode and rust.

Stainless steel is a common selection for furniture that will be used in dining applications as well because of its antibacterial properties and how easy it is to clean.

Stainless steel, as with most metals, can become very hot in sunny environments.

Note that when specifying stainless steel, you should use stainless steel hardware with it. If this is not specified, galvanized steel hardware could be used. Not only will the two types of steel look different, but the galvanized hardware could become oxidized and rust, causing it to bleed onto the stainless-steel components, which will not have corroded, but they may appear that they have.

POWDER COATED STEEL

Powder coating is the process of covering steel in a topcoat that provides a protective barrier from the elements as well as a way to add color onto the metal.

For all outdoor furniture, one of the most common types of powder coating is known as Super Durable Polyester Powder, or SPEC for short. This is high-performance coating delivers five times more weathering protection than standard polyester coating.

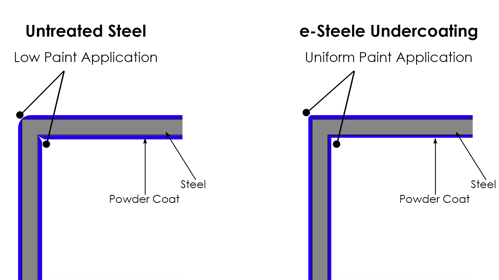

When attempting to powder coat a part that has a tight angle or a corner, electricity in the powder follows the path of least resistance and the areas adjacent to the corner offer an easier, more accessible path for the charged powder to readily flow into those areas, but not as readily to the corners, which causes them to be exposed. This is called the Faraday Cage effect.

There are ways to overcome this problem by spraying at different angles or spraying additional material to ensure coverage on these areas. But the thicker application can make coating more probable to be chipped away or picked off.

A more scientific solution is to apply an e-coating to the steel. This charges the material with a direct current. Then, when the electrostatically charged polyester topcoat is applied, it is attracted and adheres to the steel with uniform coverage over 100% of the piece. Applied at a thickness around 1 mil, this thinner coating actually cures harder, and provides more durability and protection against corrosion.

When compared to applying color with paints, powder coating is more durable in outdoor installations, and will last longer without chipping away.

We offer 22 colors to choose from and offer custom colors and color matching as an option, so you can get a piece to your desired look.

One aspect to consider before choosing a powder-coating finish is the amount of wear you expect the furnishing to receive. Things like skateboards can cause some pretty bad scratches on powder coat finishes, as well as shovels or snowplows in the winter. If you anticipate anything with rough edges coming into contact with your furnishing, powder coat may not be the best option for you.

TUBE VS PIPE

Steel typically comes in one of two forms: tube or pipe. Like finishes, there are slight differences in the steel when discussing tube vs pipe.

Tubing is commonly used for structural purposes, making it the preferred material in manufacturing and for use in site furnishings. Tubing size is specified by the outside diameter, OD, and the wall thickness, which is stated as a gauge. The lower the gauge, the thicker the tubing. The thicker the tube, the more strength it will have, and the more durable it will be.

Pipe, in contrast, is the tubular vessel commonly used in pipelines and piping systems for transferring gasses or fluids. Pipe is also used in outdoor furnishings and more commonly found with bike racks. Pipe is specified by the nominal pipe size in schedule, the wall thickness, the higher the number, the thicker the wall and more durable the pipe will be.

Our preference for outdoor site furnishings is to use tubing, primarily because of its structural characteristics.

OTHER METALS

ALUMINUM

Aluminum is typically not as strong as steel. It’s worth noting that some aluminum alloys can be stronger than certain types of steel, but for weight bearing structural elements, or applications that require considerable strength for operation, steel is often the preferred choice.

One of the advantages that aluminum has over steel is that it is significantly lighter. Aluminum is often 2.5 to 3 times less dense than steel, making it easier to maneuver. Because of this, however, aluminum will need to be carefully structured in order to maintain the strength required for outdoor furnishing applications.

Aluminum is also more flexible in its castability, allowing it to be shaped into more complex, decorative profiles than steel.

Aluminum is naturally corrosion resistant, and able to withstand long periods of rough weather conditions and wet environments.

At Thomas Steel, we use cast aluminum end frames on a few of our benches, in order to achieve a decorative profile. We prefer to use steel in all other components of our furnishings, for the strength and durability that it provides.

CAST IRON

Cast iron offers some more decorative or ornate possibilities than steel, however outdoor furnishings that incorporate cast iron tend to be a more brittle and porous than ones made of steel.

Cast iron is not a material that we at Thomas Steele have much confidence in, so, in general, we avoid the material.

IPE

Ipe is a wood commonly used in commercial outdoor furniture. It is a common choice for outdoor applications because it is incredibly hard and can stand up to abrasion and heavy use, which makes it ideal for seats or tabletops. It’s also naturally resistant to rotting, insect infestation, and growing mildew or mold.

Ipe has a reddish-brown to olive brown color when new but will weather to a silver-grey over time.

Over time, cracks and checking may show up on Ipe boards, however this is natural and does not impact the structural integrity of the board or any of its properties to combat natural deterioration.

If your intention for a site furnishing is to just set it and forget it, Ipe may not be the best choice for you. Over time, heavily weathered boards will change color and can become slightly rougher to the touch. But the original qualities of the wood can easily be restored with a light sanding and a new application of oil. To keep the boards looking as fresh as the day they were installed, we recommend an annual application of sealant.

Site furnishings with Ipe are a great compliment for landscape designs because of the natural look of the wood. Ipe is also great for warmer climates, as the wood does not get as hot in the sun as steel would. The wood also isn’t affected by salts, making it ideal in coastal climates as well.

RECYCLED PLASTIC

At Thomas Steel, our recycled plastic boards are made of high-density polyethylene, HDPE, that is comprised of, at minimum, 95% recycled post-industrial and/or wide spec plastic.

We offer two different types of recycled plastic boards: standard recycled plastic and embossed recycled plastic.

Standard recycled plastic resembles solid lumber boards and is available in a handful of colors.

Embossed recycled plastic comes in boards that have been crafted to more closely resemble wood in both color and texture.

The difference between the two types of plastic boards is primarily aesthetic.

Recycled plastic is one of the most environmentally durable materials you can specify. The material will not rot, splinter, crack, or grow mold. It is impervious to insect infestation, is resistant to graffiti, and does not dull from UV rays.

One downside to recycled plastic is the structural strength. If not properly supported, boards will sag underneath their own weight. At Thomas Steele, we assure that there is adequate framing to properly support recycled plastic boards on all of our products.

Additional Notes

You can request a free material sample package that we will send out to you, so you get a better sense of the materials and finishes discussed here.

If these are the types of site furnishings you would like to explore further, consider downloading the Thomas Steele catalog, where you can discover a broad portfolio of outdoor site furnishings you can use to create a stylish and functional outdoor space that lasts for years.

Related Resources